Domestic robots being mass-produced and put into use at an automotive OEM for the first time

2024-11-18 11:40:16

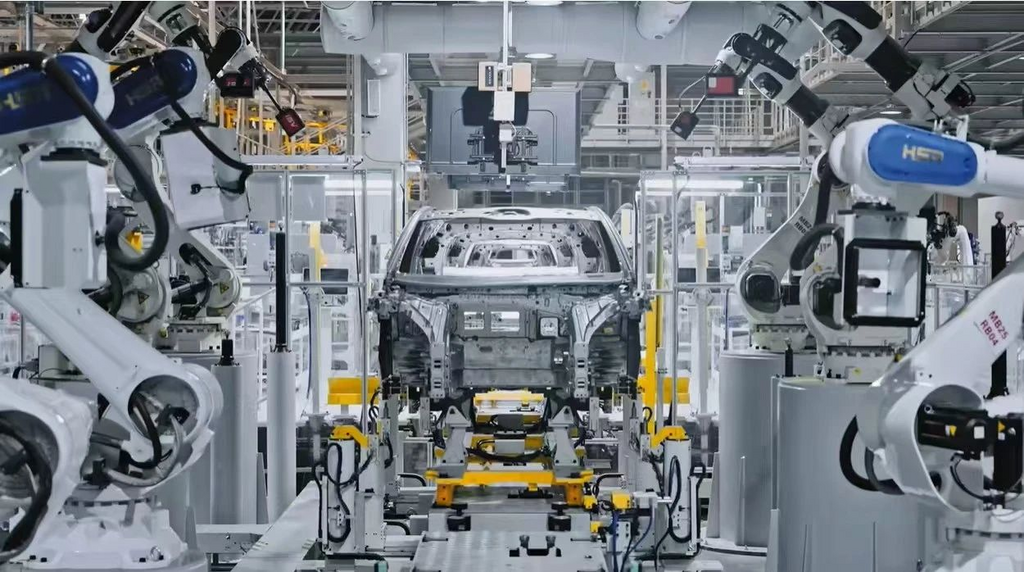

CHONGQING (CQNEWS) -- In October of this year, Changan Auto's smart factory was unveiled in Chongqing, which is the largest 5G automobile factory in the world. Particularly, domestic robots “go on duty” at multiple workstations, including weld point detection, side gluing, and body arc welding, marking the first large-scale application of domestic robots at an automotive OEM.

Walking into the factory, you can see that the automated production lines, composed of nearly a thousand robots, makes it look full of technology. These robots are independently developed by Chongqing Huashu Robotics Co., Ltd., a company located in Chongqing Liangjiang New Area.

Among them, at the weld point detection station, robots can identify the shape, size, location, and any defects of the weld points using ultra-high-definition visual cameras, and compare them with preset standards to automatically determine whether the weld quality is qualified, thereby ensuring the strength and reliability of the welding structure.

At the sunroof and windshield body priming coating workstation, the robot can obtain information such as different vehicle models through a 3D camera, identify sunroof and windshield components of various shapes and sizes, and automatically adjust the spraying trajectory and parameters. At the same time, by using a 2D camera, it automatically identify the width and uniformity of the priming coating trajectory, allowing it to judge whether there are any quality defects in the trajectory and record this information in real time.

The head of Huashu Robotics introduced that the mass application of domestic robots at a world-class automobile manufacturing base marks a new breakthrough in China's robotics industry. Based on this, Huashu Robotics has also established a standardized product technology platform that can provide more competitive products and solutions for the market.

It is learned that since its establishment 8 years ago, Chongqing Huashu Robotics Co., Ltd. has tackled over 300 critical technologies and core system challenges of industrial robotics by relying on its R&D team and collaborative innovation, obtained more than 200 independent intellectual property rights, and developed over 50 types of industrial robots.

Liangjiang New Area serves as the main carrier area for Chongqing's robotics industry, currently housing 26 robotics and supporting enterprises. 10 robotics R&D, testing, and incubation platforms have been established here, including the National Robot Test and Assessment Center and Chongqing Luban Robot Technology Research Institute Co., Ltd., promoting the integrated development of the robotics innovation chain, industrial chain, and application chain. (Translated by Jane, Fathom Language Limited)

Editor:江夷玮

手机阅读分享话题

手机阅读分享话题